Content overview

This guide breaks down the essential components of fleet management, from its foundational principles to the latest technologies shaping the future. You'll learn key terms like TCO and asset utilization, explore strategies to improve fleet efficiency and discover how platforms like Fleetio are helping real-world teams turn data into action. Whether you're new to the field or looking to sharpen your strategy, this is your starting point.

Jump to a topic

Fleet management is a major component of any business that relies on mobile assets to deliver goods, provide services or, generally, to get a job done. It involves overseeing, maintaining and optimizing a company’s fleet operation to ensure it runs efficiently and safely. Whether you’re stepping in to manage a small local delivery service or a larger logistics operation, effective fleet management is essential to keeping the fleet running — and revenue flowing. After all, effective fleet management directly impacts a business’s bottom line and operational success.

Successful fleet managers are able to better control costs by minimizing fuel and maintenance expenses while ensuring safety for drivers and the public, maintaining compliance with fluctuating regulations and boosting efficiency by keeping assets productive. Conversely, less successful fleet management can put companies at risk through increased expenses and downtime —- not to mention dissatisfied customers — all of which can erode profitability and reputation.

Fleet Management 101

What is Fleet Management?

As previously mentioned, fleet management requires overseeing, maintaining and optimizing fleet assets and the operation as a whole, but what does that really mean? Well, it means managing costs and ensuring assets function reliably and safely. It also means overseeing the people who operate and maintain those assets. It’s a balancing act that requires both strategic planning and day-to-day oversight, tailored to the unique needs of each fleet. And, sure, that may not sound like a lot on paper — or screen, rather — but it takes a ton of effort and data to thrive as a fleet manager.

Everything we do in this company needs fleet [...] whether that's deliveries, whether that's vegetation management, whether that's making sure that bucket truck rolls so that they can go out and restore the power, right? Nothing really happens in any company that has vehicles without those vehicles running and doing what they need to do. Bob Polka, Director of Fleet Operations, Treeways

History of Fleet Management

Speaking of data, fleet management has come a long way from its antiquated beginnings. In the 1970s, the introduction of standardized maintenance reporting and early electronic ordering systems marked a turning point. The 1980s brought desktop computing, giving managers direct access to fleet data. By the 1990s and 2000s, web-based systems and technologies like GPS and telematics revolutionized the field, shifting the role from hands-on mechanical oversight to a blend of financial, analytical and administrative responsibilities. Today, fleet management is a tech-driven discipline that continues to evolve with innovations like automation — both operational and vehicular — and electric vehicles (EVs).

Terms You Need to Know

Before we dive further into fleet management, let’s look at a few key terms you might want to know:

- Total cost of ownership (TCO): TCO measures the full cost of owning and operating a fleet asset, including acquisition, maintenance, fuel, depreciation, and administrative expenses. It’s a critical metric for budgeting and deciding when to replace an asset.

- Cost per mile (CPM): CPM tracks the cost of operating an asset per mile driven, helping managers monitor fuel efficiency, maintenance needs and service expenses.

- Asset utilization: Asset utilization is the average use (miles or hours) of assets daily. This metric can help you determine if an asset is being over- or underutilized so you can adjust its use to maximize asset ROI.

- Asset lifecycle: Asset lifecycle is the lifespan of an asset from acquisition to disposal and a critical metric for influencing vehicle replacement strategies.

New to Fleet Management?

Our Fleet Manager’s Manual is packed with tips, advice and successful management strategies from experts across multiple industries.

Check it outThe Core Pillars of Fleet Management

Running Assets Reliably & Safely

If an asset doesn’t run, is it really even an asset, or is it just very expensive yard art? Keeping assets — and the fleet as a whole — running should be one of your top priorities as a fleet manager. This includes things like performing daily inspections, managing fuel and creating a solid asset replacement and procurement plan. Regular pre-trip inspections ensure assets meet safety and compliance standards, but they also help catch issues before they become costly problems which, in turn, helps reduce repair costs and unscheduled downtime.

When it comes to fuel management, you may be surprised at the amount of asset health data you can gain from fuel-related metrics. Whether you’re using fuel cards, telematics or a fleet optimization platform, collecting fuel data allows you to spot trends in fuel purchases and consumption. Using this data, you can determine where and why fuel spend may be inflated for a particular asset, such as a mechanical issue, driver behavior issue, utilization imbalance or the asset is simply nearing the end of its useful life — which leads us to replacement and procurement strategies.

Managing when to replace assets — based on mileage, hours, years in service or maintenance and repair costs — keeps the fleet reliable and avoids the pitfalls of aging assets. When considering replacing an asset you’ll want to determine things like:

- What does the annual maintenance cost? How does it compare to the total cost of a lease?

- How many miles/years/hours will your replacement strategy revolve around?

- How often would you have to renew or start a new lease program?

- Are there certain lease restrictions (like customizing an asset or mileage) that don’t coincide with your needs?

- On average, what return are you able to get when reselling an asset you’re ready to replace?

Repairing Assets Quickly

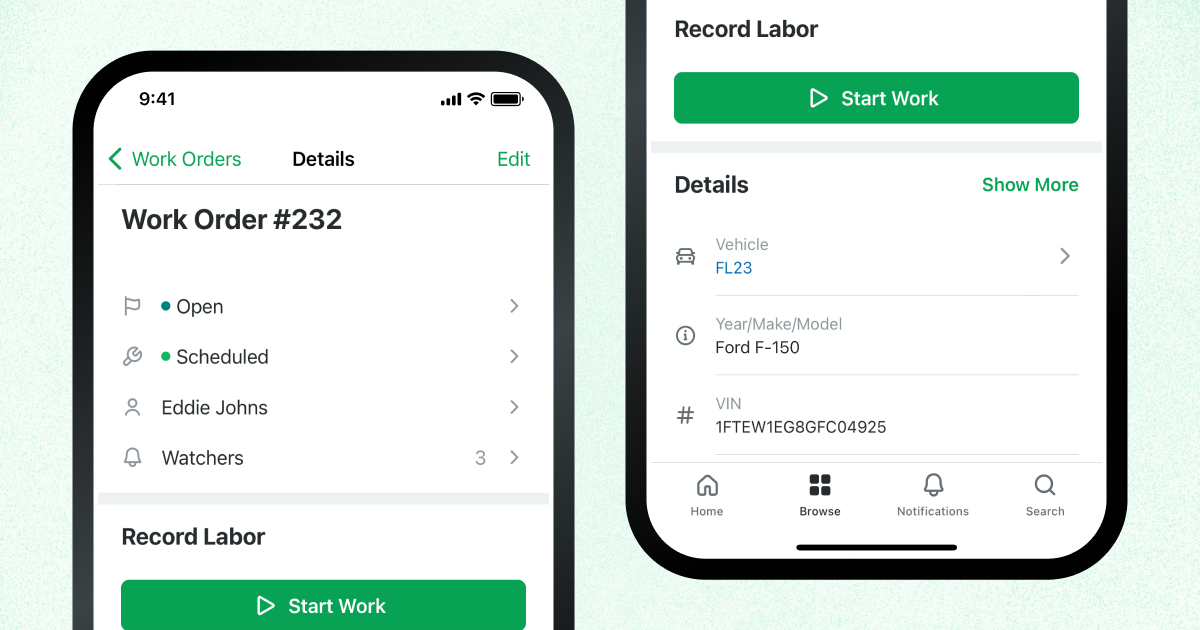

Assets — or asset components — are going to break from time to time. It’s just the nature of fleet. But that doesn’t mean you can’t mitigate the chances of unscheduled downtime through the aforementioned inspections and a solid preventive maintenance (PM) plan. Proper PM helps prevent breakdowns, reduces unscheduled downtime and extends asset life. Adhering to OEM PM schedules should be the base model for PM planning. Over time, service data can show you trends that allow you to tweak PM schedules for the best outcome.

For occasions when a breakdown does occur, ensuring expedient repairs can be crucial, meaning prioritizing issues and minimizing shop delays is pretty important. Prioritizing issues — low, moderate, critical — allows you to schedule service in such a way as to reduce the unexpected downtime, whether that means taking it to a shop or pulling one of your technicians off a low-priority task to address a critical issue. Also, keeping replacement parts on hand can speed up repairs, minimize further delays and get assets back to work faster.

Optimizing Your Fleet Operation

Fleet optimization is a bit of an ever-ongoing process. You start by improving one aspect of the operation and move on to the next and, by the time you’ve made improvements across the whole fleet, you start seeing ways you can improve upon the improvements. Before you make any changes or potential improvements — and not every change will be a success, so it’s important to be okay with failing before getting it right — you need to know what needs improving and why. Track metrics like fuel consumption, asset utilization, PM and inspection compliance rates and service costs to identify areas for improvement.

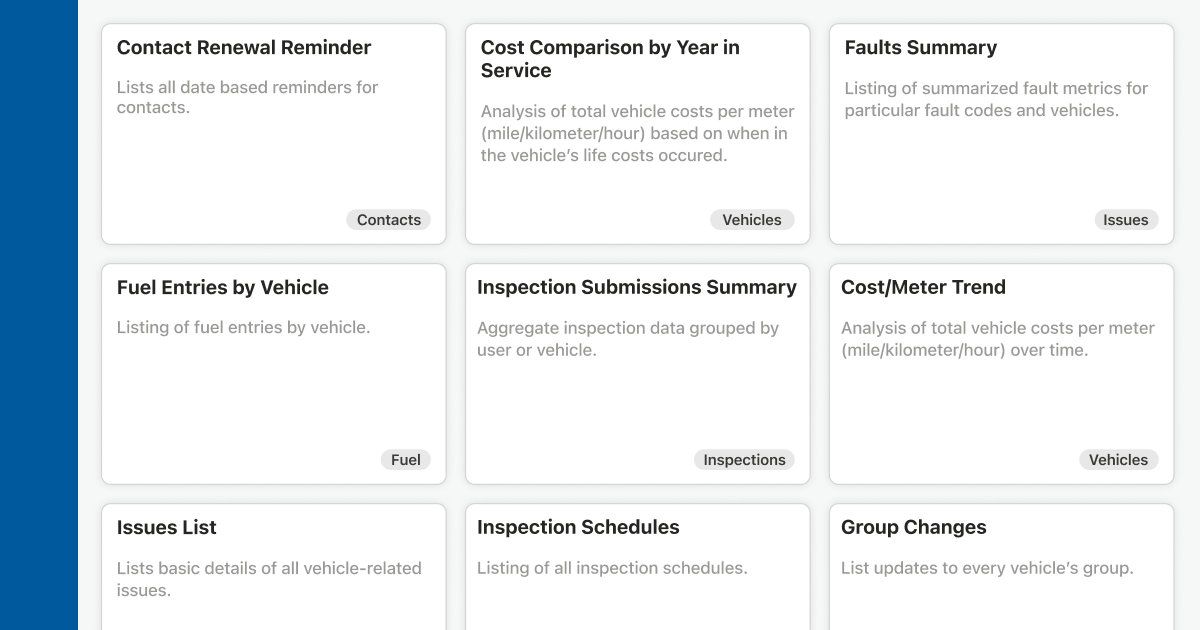

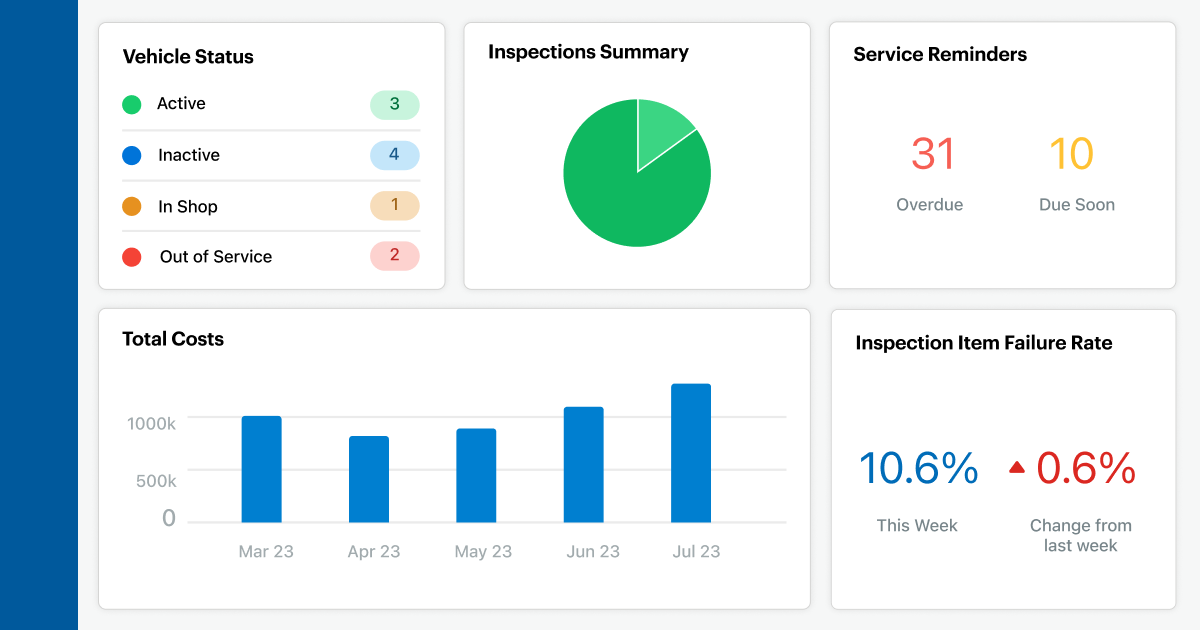

Tools like Fleetio’s fleet optimization platform — hey, I’m not above a shameless plug — automate data collection and aggregation, and can integrate with other fleet and business solutions so you can see all your data in one place. And it collects a lot of data. Like, a “this is kind of overwhelming” amount of data. Fortunately, the customizable dashboard and configurable reporting allow you to keep the data you need to see on the daily front and center. This type of real-time data access broken down into more easily digestible graphics, like charts and graphs, makes the data easier to analyze quickly so you know just what part of the operation needs a little optimization magic.

Fleet Management Technologies

As we saw earlier, fleet management has begun leaning heavily on technology over the past decade… or two. But it’s important to note that not every fleet technology is going to be right for every fleet, which means you need to understand your fleet’s needs before dropping Benjamins on something that may not be the best fit.

Telematics, for instance, is perfect for tracking asset locations, driver behavior, DTC fault alerts and even sensor data. On the other hand, you may benefit from automation tools and integration features found in optimization platforms for more robust data access. These types of technologies can help you improve fleet operations by reducing fuel waste, increasing safety and asset performance through real-time alerts, and lowering costs by streamlining operations.

Let’s look at a few different technologies and break down what problems they tackle and what benefits you can gain from them:

- AV technology: AV tech’s main focus is safety, and Level 0 and 1 autonomy is offered by most OEMs. This covers such safety features as automatic emergency braking, collision warning, lane departure warning, adaptive cruise control and lane keeping assist, according to the NHTSA. Investing in vehicles that use low level autonomy can improve your fleet’s safety. Level 2 autonomy, which offers hands-free driving — the driver does still need to pay attention — is the latest to hit the market and hasn’t been widely adopted.

- GPS: GPS tracking is offered by both OEMs and third-party providers and focuses on tracking and monitoring goings-on behind the wheel and on the road, including speeding and harsh driving, route adherence and, of course, vehicle location. GPS is great for smaller fleets just looking to track a few vehicles locally.

- Telematics: Telematics uses GPS tracking and onboard diagnostic reading capabilities to monitor the health of fleet assets. While some automotive OEMs offer embedded telematics, many fleets rely on telematics providers who offer a combination of plug-in hardware with software that manages the data pulled from the assets. Telematics tends to focus on compliance and fleet health, whereas GPS is more at the asset level. While many fleets are required to use telematics for regulatory reasons, those not required can still find major benefits in using telematics to track fleet health.

- Connected vehicle APIs: While a majority of the vehicles on the road in the United States today are connected, using connected vehicle application programming interface (API) technology is still quite new. Connected vehicle APIs will potentially offer the same benefits as telematics and are focused primarily on EVs and other vehicles that don’t offer access to an OBD port — which is how telematics devices collect data. While some OEMs offer this technology, it may not yet be mature enough to benefit fleets that have telematics-compatible assets.

- Custom-built maintenance/management systems: Companies can have fleet management systems custom built. Software companies offer different means of data storage, including in-house hardware and cloud-based storage. While having a maintenance or management solution built can help ensure it does what the fleet needs, it can be a costly technology that is difficult to scale as your company grows.

- Fleet management and optimization platforms: Generally provided by software companies, fleet management and optimization platforms focuse on boosting fleet efficiency in several ways. These solutions track fleet data and provide integrations and APIs with other technologies to allow data consolidation across your entire operation for improved fleet performance monitoring. Additionally, they aggregate collected data into easy-to-read reports you can send to stakeholders so everyone can quickly see the metrics they need to influence decisions. They also offer a certain level of fleet management automation via auto-approvals with set parameters and automated maintenance workflows.

Don't be enamored with the technology first. Focus on what problems that need to be solved first. Where are you losing money? Where are you losing time? Where are you losing customer satisfaction? And then from there, understand whether or not autonomy can solve those problems for you. Adam Campbell, Senior Manager of Safety Innovation & Impact, Gatik

See how fleets are making the most of these technologies

As fleet technology continues to evolve, it becomes increasingly necessary for fleet managers to understand what technologies are available to them and how these technologies work together. Let’s take a look at a how a few of our customers use Fleetio with other fleet technologies to get the most out of their fleets:

- City of Cambridge: When Tom Rowlings came to City of Cambridge as assistant fleet manager, he was tasked with finding an approved FMS that would integrate with the fleet’s current telematics provider, Samsara, help the team be more collaborative and collect stronger data. City of Cambridge’s previous FMS was poorly implemented and not the right fit, so Tom pulled everything back to paper and spreadsheets, leading to delayed communication and regular process interruptions. After implementing Fleetio, City of Cambridge has improved service times, streamlined operation-wide communication and consolidated fleet data for more actionable insights to help drive change.

- Asplundh Australia: The team at Asplundh Australia used to lose significant time chasing down monthly foreman audits, tracking down under-utilized pieces of fleet when mobilizing contracts and filling out repetitious forms. After integrating its business system, Microsoft Power BI, and its telematics system, Fleet Complete, into Fleetio, the team at Asplundh was able to cut form clutter to boost productivity and consolidate data — specifically regarding utilization — for precision contractor billing and contract mobilization. This also significantly increased ROI for seasonal assets.

- J. Pettiecord, Inc: The fleet at J. Pettiecord was running up against issues with its previous fleet maintenance solution, which necessitated continual use of paper forms and manual data entry. The company determined it needed a solution that would automate data entry, streamline the fleet’s maintenance process and consolidate data sources, including data from its telematics provider, Samsara. After electing Fleetio as its FMS, J. Pettiecord enhanced maintenance efficiency with digital work orders and improved maintenance communications with status updates, notes and photographs of completed work. Team members can now quickly and easily submit customized digital vehicle inspections, and with Fleetio’s open application programming interface (API), J. Pettiecord’s data is consolidated to a single platform for comprehensive reporting.

How to Improve Fleet Management

Having access to robust and reliable fleet data puts you in a better position to improve your operation and grow as a fleet manager. Consolidating data around fuel, maintenance and utilization, makes it easier to track specific metrics and spot trends you can act on for improvements. The automated workflows don’t hurt either. Setting PM and scheduled service alerts helps ensure PM compliance and improved uptime, and having inspection item failures alert you in real time makes it easier to manage priority tasks. Plus, there’s the added benefits of better cost control and reduced downtime.

Challenges of Fleet Management

There are a number of challenges to contend with as a fleet manager, both internally and externally. Fuel, for instance, is typically the largest recurring fleet expense, but can be hard to budget for given market shifts can affect fuel prices. Maintenance and repairs are usually the second largest cost for fleets and, as assets age, those costs climb, demanding careful tracking and cost-saving measures to offset higher expenses.

There’s also the labor shortage aspect to consider, both with drivers and technicians. Finding and keeping skilled employees can be a feat of its own, meaning competitive pay, sign-on bonuses and training programs might need to be discussed as a potential solution. On the topic of training, staying current with technologies, whether fleet management solutions or EVs and autonomous vehicle (AV) technology can require investment and upskilling. Also, there’s regulatory compliance to contend with, as rules on emissions, safety and hours of service are complex and ever-changing.

Emerging Trends & Future of Fleet Management

The future of fleet management is an evolutionary one, especially as more and more new technologies become available. EVs, for instance, tout lower fuel costs and emissions, while AVs aim to boost safety and efficiency. AI-powered tools are emerging to predict maintenance needs and optimize routes. These trends may make fleets greener, smarter and more proactive, reshaping how managers operate in the years ahead.

It's not just about technology, it's about what pain point you're solving for. And there are a lot of pain points in the middle mile and a lot of value that they – our customers – can provide to their customers by unlocking value, safety and efficiency and cost, by adopting autonomy. We are very intentional with our deployment. Adam Campbell, Senior Manager of Safety Innovation & Impact, Gatik

Gain visibility into your fleet operations

Whether you’re new to fleet management or a veteran brushing up on the basics, Fleetio’s fleet optimization platform may be worth investigating.

Take a lookFAQs

What is fleet management?

Fleet management involves overseeing and optimizing a company’s mobile assets to ensure efficiency, safety and cost-effectiveness.

Why is fleet management important?

It helps reduce operational costs, extend asset lifespan, improve safety and ensure compliance with industry regulations.

What technologies are used in fleet management?

Technologies include telematics, GPS tracking, fleet management and maintenance software and fleet optimization platforms, like Fleetio.